How it works

Revolutionizing Aquaculture: Our BO RAS System

01

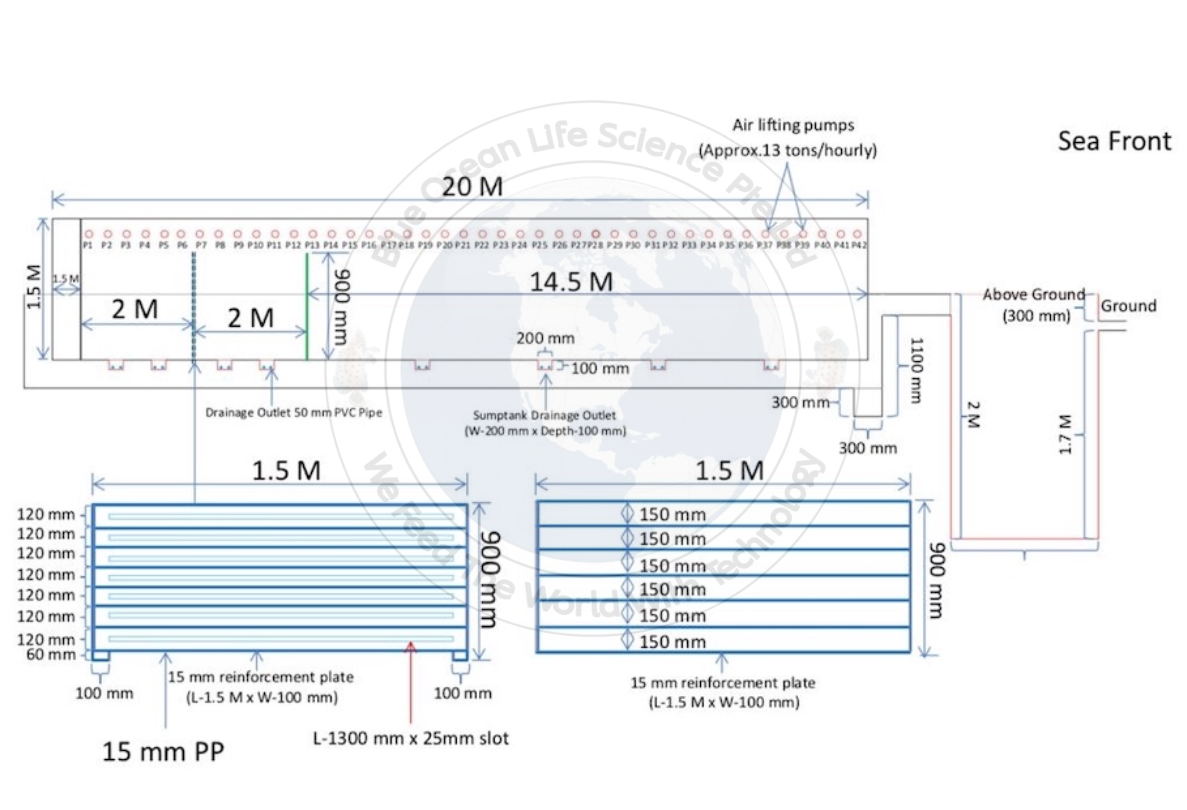

Removing Pollutants from Seawater

Polluted seawater from farming tanks enters our system and is passed through specially designed blue ocean trays to effectively filter out floating toxic organic matter within the size range of 1000 - 2000 microns. To ensure swift waste disposal, the filtered waste undergoes rapid discharge through a double super flushing funnel.

02

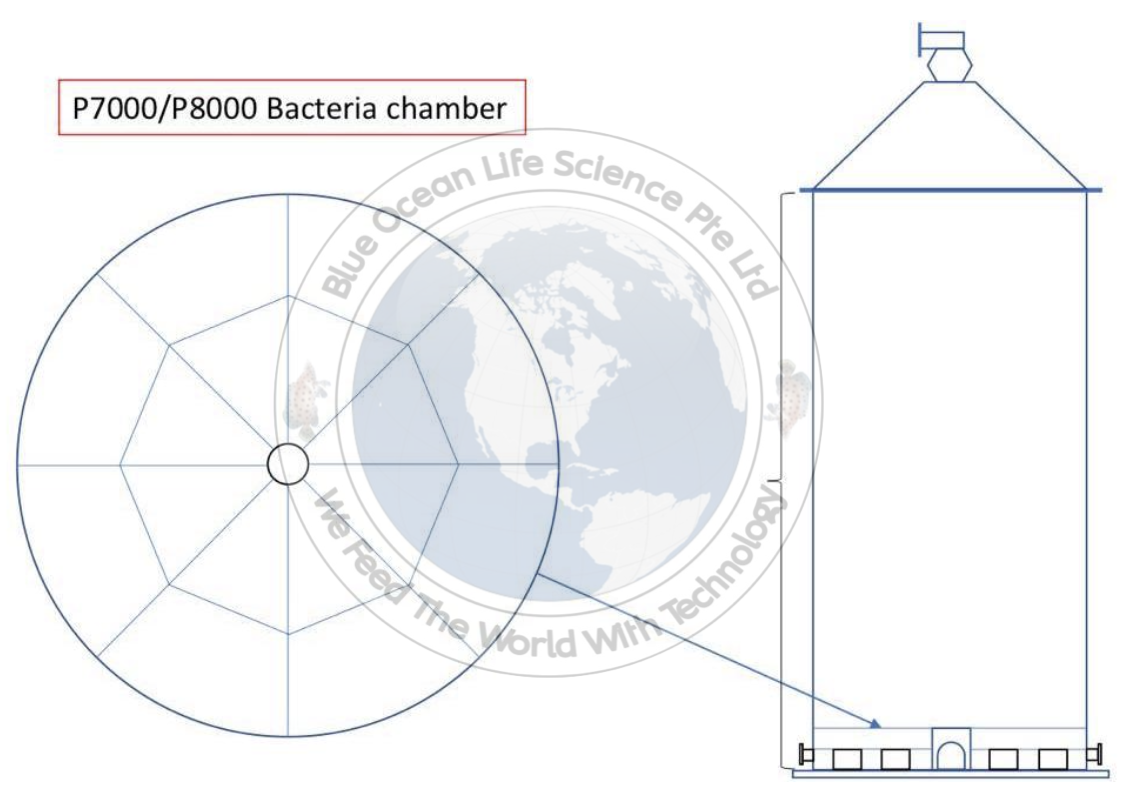

Removing Semi-Dissolved Organic Matter

Following Stage 1 filtration, the filtered water proceeds to the P7000/P8000 chambers equipped with specially designed voltex filters. This crucial step effectively removes semi-dissolved floating toxic organic matters within the size range of 1000 - 5000 microns, ensuring enhanced water quality.

03

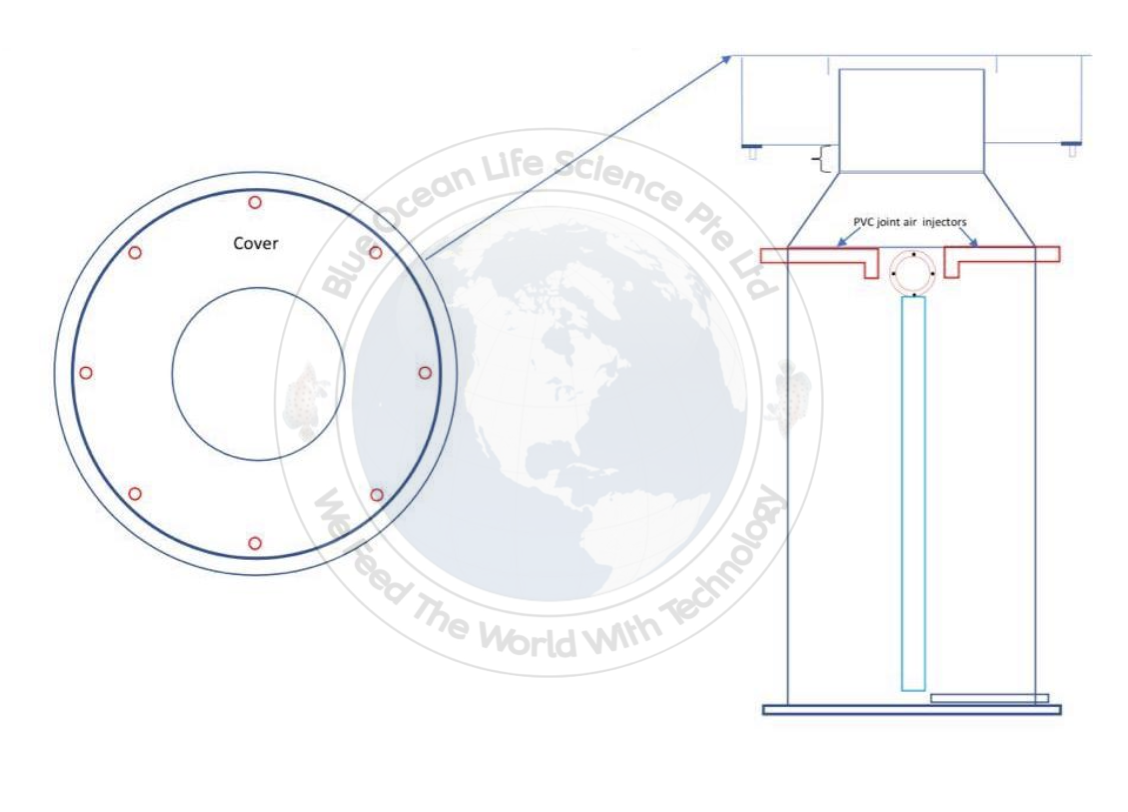

Toxic Extractor and Oxygenator

To further enhance water purity, we employ a specialized toxic extractor cum oxygenator. This innovative device effectively extracts dissolved organic matters within the size range of 0.1-25 microns, contributing to a healthier aquatic environment.

04

P7000 Biological Filter System

Upon successfully eliminating toxic organic matter, our advanced P7000 biological filter system comes into play. This sophisticated system efficiently converts ammonia into nitrite and further transforms it into harmless nitrate, ensuring a safe and sustainable aquatic environment.

05

P8000 Denitrator Filter System

Concluding the purification process, our P8000 denitrator filter system takes center stage. This innovative system achieves the conversion of nitrate into nitrogen gas, effectively eliminating it from the water at an impressive rate of 7 liters per minute.

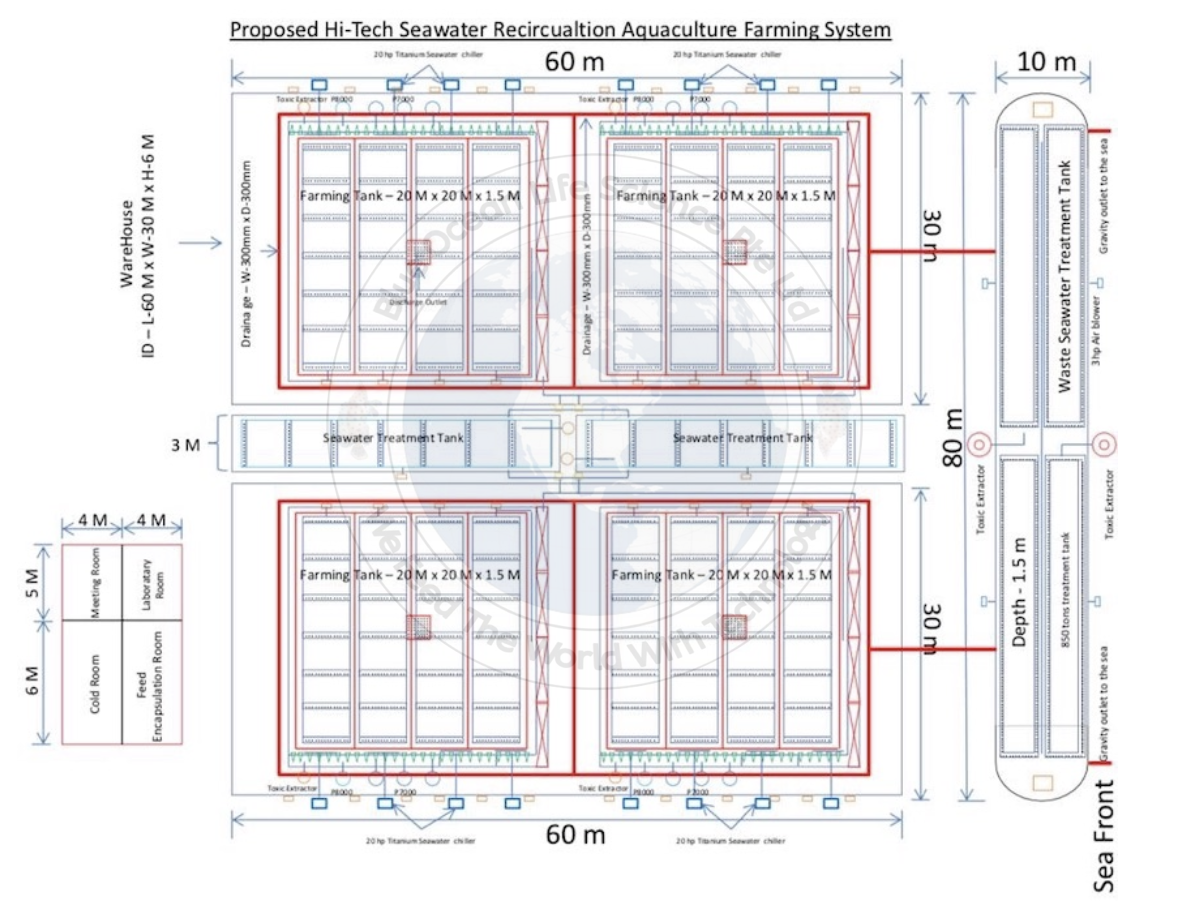

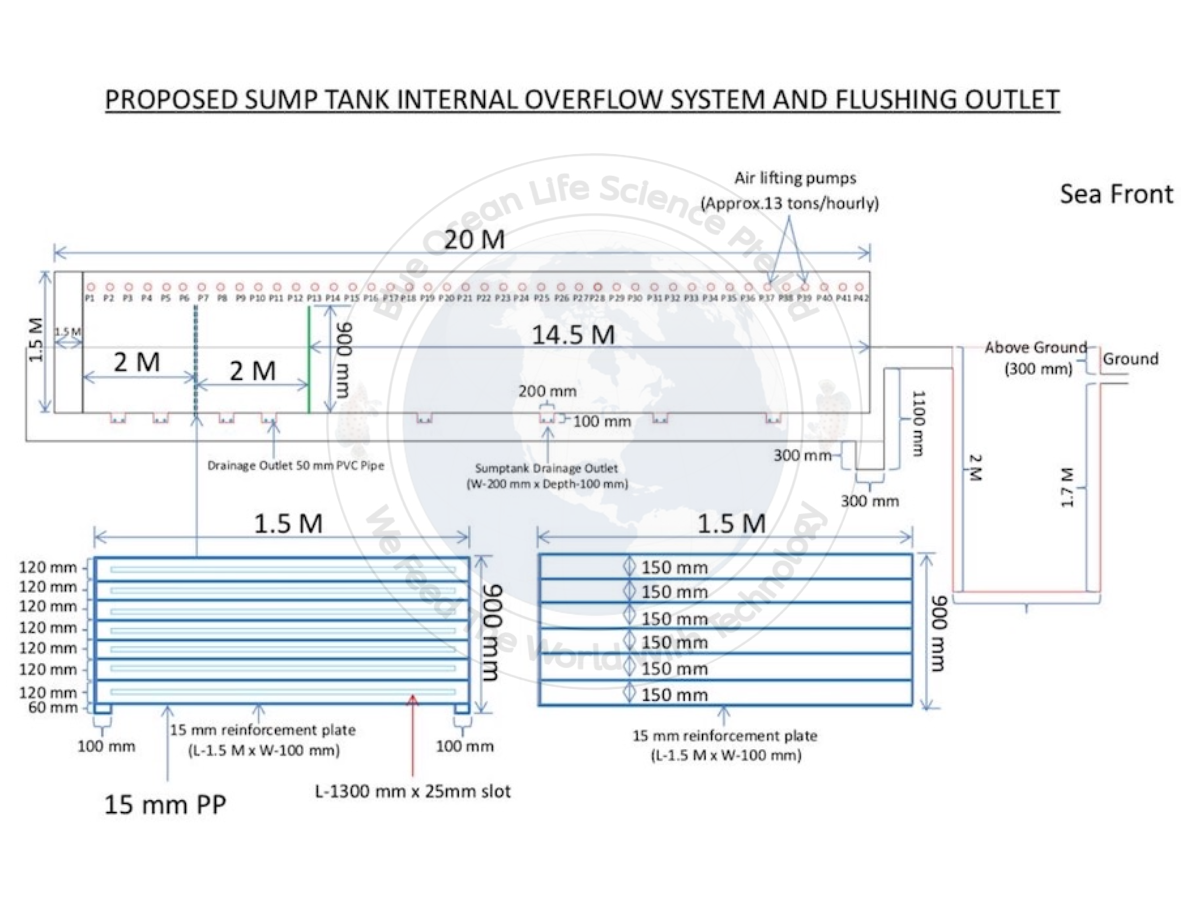

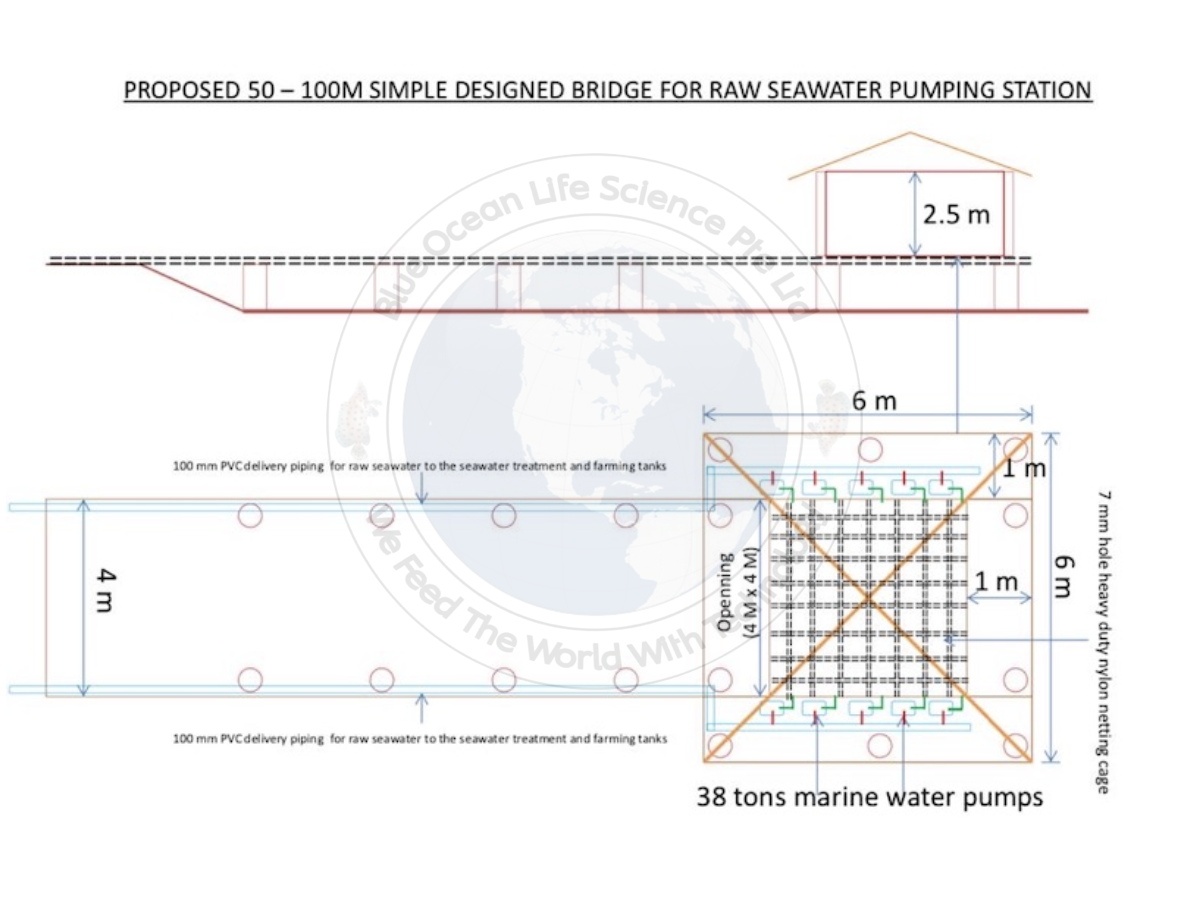

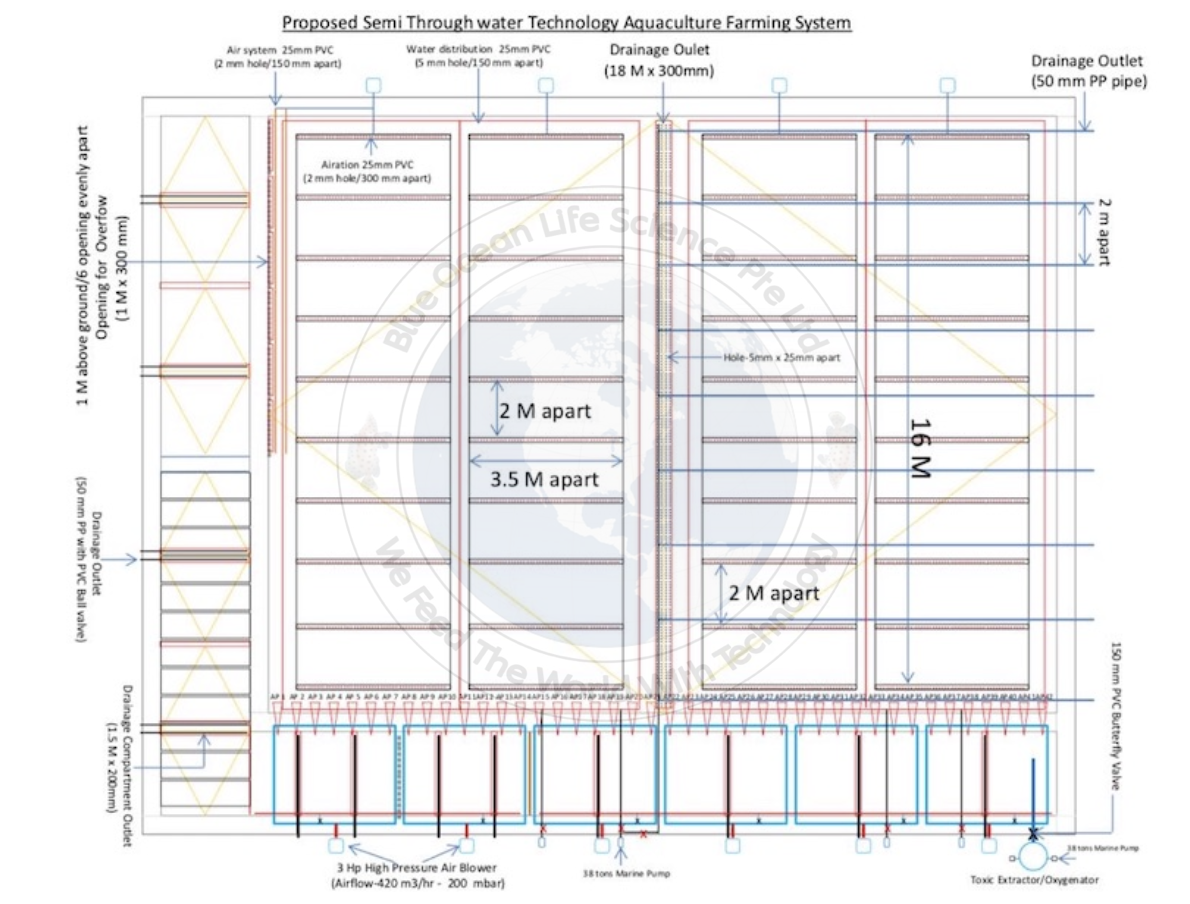

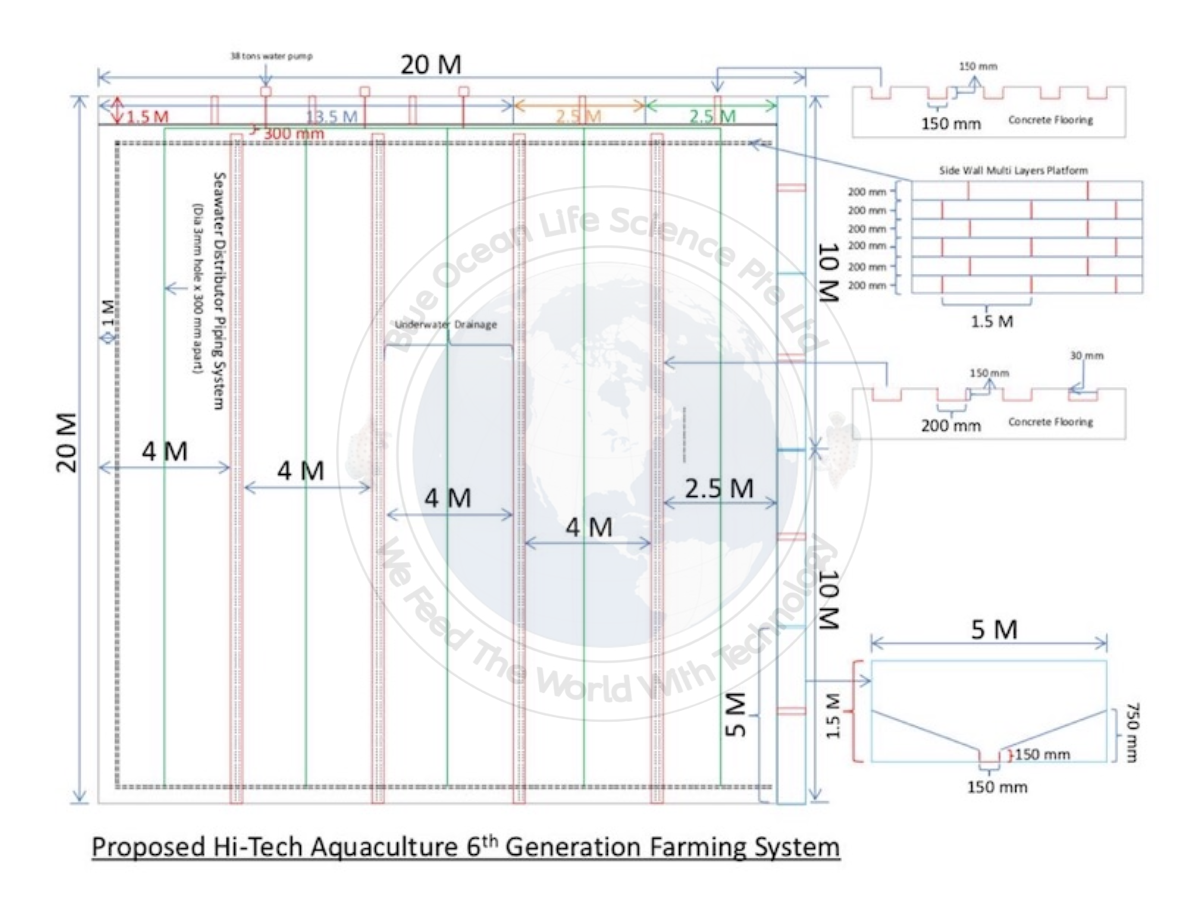

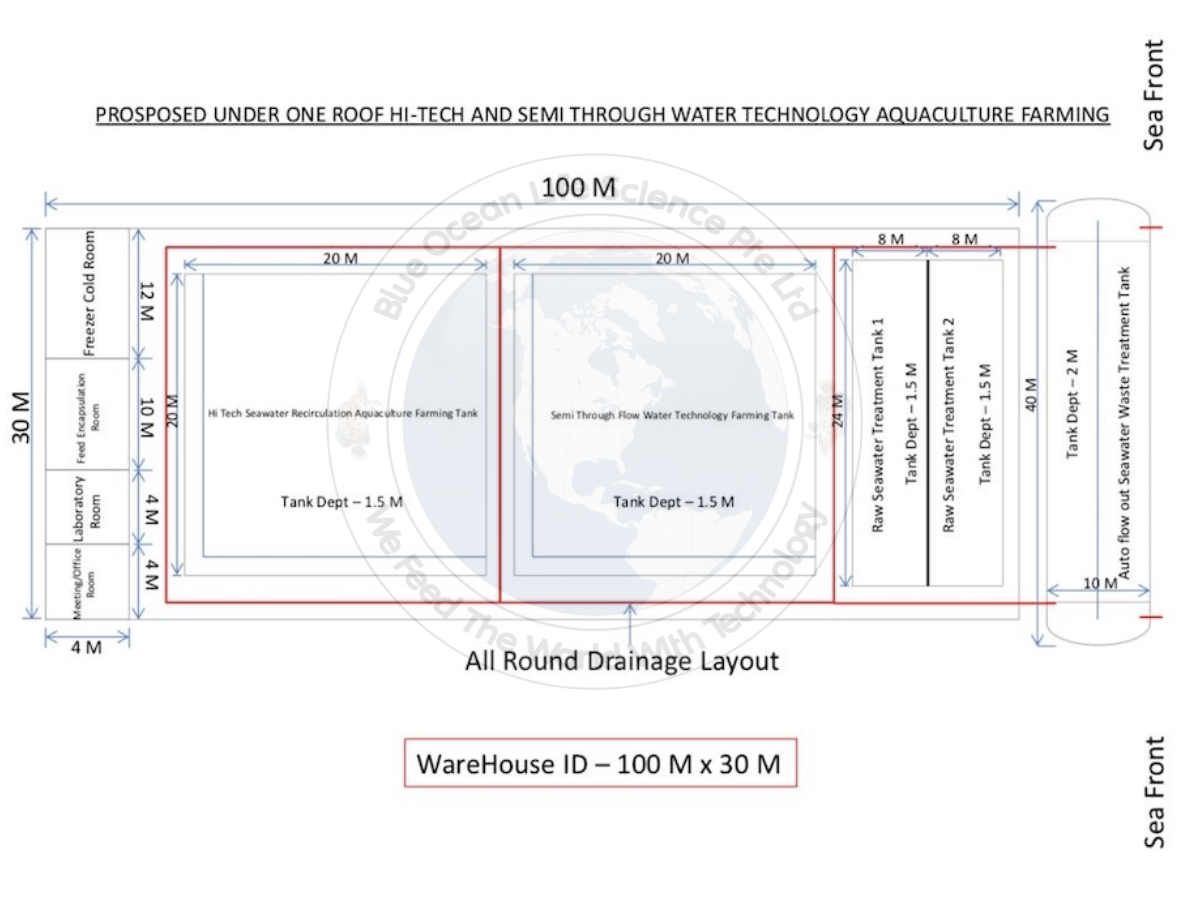

The technology

Design Concept for the BO Ras System

The cost

Financial Projections

*Assumes 1 tank of 20×20 tank capacity of 15000 fish frys with 90% survival (Capable to achieve higher % survival rates) resulting in 13,500 pieces of 1.25 kg - 1.5 kg of Hybrid grouper per harvest; 1 harvest in 12 months.

| FY21 (1 harvest) | FY22 (1 harvest) | FY23-FY24 (1 harvest) | |

|---|---|---|---|

| Hybrid Grouper | |||

| Prices per pcs (SGD) | 40 | 40 | 40 |

| Output (# of fish) | 13,500 | 13,500 | 27,000 |

| Rev per fish type (SGD) | 540,000 | 540,000 | 1,080,000 |

| Total rev | 540,000 | 540,000 | 1,080,000 |

| Cost | |||

| Manpower | 108,000 | 108,000 | 216,000 |

| Water vitamins & minerals | 87,600 | 87,600 | 175,200 |

| Fish fry | 30,000 | 30,000 | 60,000 |

| Feed | 60,750 | 60,750 | 121,500 |

| Total utilities | 48,000 | 48,000 | 96,000 |

| Misc (A&P, admin, etc) | 50,000 | 50,000 | 100,000 |

| Capex (est) amortisation | 200,000 | 200,000 | 400,000 |

| Total cost | 276,350 | 276,350 | 552,700 |

| Net revenue (before EBIT) | 263,650 | 263,650 | 527,300 |

Cost Breakdown (SGD)

| Manpower | |

|---|---|

| Consultant fee | 3,000 |

| Farm manager | 2,000 |

| Farm assistant | 1,200 |

| Admin | 800 |

| Farm worker (4) | 9,000 |

| Water vitamins and minerals | 87,600 ($0.30-$0.50 per ton of water. A 400 sqm tank requires 480 tons of water) |

| Fish fry | $2 per piece, 15,000fry per tank |

| Live feeds | $3 per kg |

| Estimated Capex | 800k - 100k for design and build of the 1 tank BO system, including warehouse, concrete tanks, piping systems, etc 700k Only applying 4 years amortization accordingly to FRS |

| Total Utilities | Seed $4,000 per month per tank, solar energy panel recommended |

*1 tank of 20×20 tank capacity of 10000 - 100 grams of lobster frys with 90% survival (Capable of achieving higher % survival rates) resulting in 9,000 pieces of 450 grams of lobsters per 6 months harvest; 2 harvests per year.

| FY21 (2 harvest) | FY22 (2 harvest) | FY23-FY24 (4 harvest) | |

|---|---|---|---|

| Bamboo/Bersi/Mutiara | |||

| Prices per pcs (SGD) | 45 | 45 | 45 |

| Output (# of fish) | 18,000 | 18,000 | 36,000 |

| Rev per fish type (SGD) | 810,000 | 810,000 | 1,620,000 |

| Total rev | 810,000 | 810,000 | 1,620,000 |

| Cost | |||

| Manpower | 108,000 | 108,000 | 216,000 |

| Water vitamins & minerals | 87,600 | 87,600 | 175,200 |

| Fish fry | 84,000 | 84,000 | 168,000 |

| Feed | 36,000 | 36,000 | 72,000 |

| Total utilities | 48,000 | 48,000 | 96,000 |

| Misc (A&P, admin, etc) | 50,000 | 50,000 | 100,000 |

| Capex (est) amortisation | 200,000 | 200,000 | 400,000 |

| Total cost | 613,600 | 613,600 | 1,227,200 |

| Net revenue (before EBIT) | 196,400 | 196,400 | 392,800 |

Cost Breakdown (SGD)

| Manpower | |

|---|---|

| Consultant fee | 3,000 |

| Farm manager | 2,000 |

| Farm assistant | 1,200 |

| Admin | 800 |

| Farm worker (4) | 9,000 |

| Water vitamins and minerals | 87,600 ($0.30-$0.50 per ton of water. A 400 sqm tank requires 480 tons of water) |

| Fish fry | 100 g Bamboo & Bersi are $4.2 per piece, 10,000 fry per tank |

| Live feeds | $5 per kg |

| Estimated Capex | 800k - 100k for design and build of the 1 tank BO system, including warehouse, concrete tanks, piping systems, etc 700k Only applying 4 years amortization accordingly to FRS |

| Total Utilities | Seed $4,000 per month per tank, solar energy panel recommended |